As worldwide demand for sustainable, cost-competitive energy storage solutions escalates at an unprecedented pace, sodium-ion (Na-ion) batteries have emerged as a high-impact alternative to legacy lithium-ion platforms. Boasting readily available raw materials, enhanced safety credentials, and promising performance benchmarks, Na-ion battery technology is witnessing rapid traction across electric mobility, grid-scale energy storage, and consumer electronics sectors. But beneath their innovative value proposition lies a pivotal inquiry: what constitutes the exact manufacturing workflow and material composition of these cutting-edge cells?In this article, we delve into the comprehensive production workflow of sodium-ion batteries—highlighting each critical stage that transforms raw materials into high-performance, commercially viable energy storage units.

The foundation of any battery lies in its chemistry, and sodium-ion batteries primarily rely on earth-abundant elements such as sodium, iron, manganese, and carbon. Unlike lithium, which is geographically concentrated and subject to supply chain volatility, sodium is readily available in seawater and mineral deposits worldwide. The cathode typically employs layered transition metal oxides (e.g., NaNi₁/₃Mn₁/₃Co₁/₃O₂), Prussian blue analogs, or polyanionic compounds, while the anode commonly uses hard carbon derived from biomass or petroleum pitch. Electrolytes consist of sodium salts—such as NaClO₄ or NaPF₆—dissolved in organic carbonate solvents. Before entering the production line, all active materials undergo rigorous purification, drying, and particle-size optimization to ensure consistent electrochemical behavior.

Once raw materials are prepared, they are mixed into homogeneous slurries tailored for either the cathode or anode with strict ratio control. The cathode slurry combines active material, conductive additives (like carbon black), and a polymeric binder (commonly sodium carboxymethyl cellulose or PVDF) in a compatible solvent, with thorough stirring to ensure uniform dispersion of each component. Similarly, the anode slurry blends hard carbon with binders and conductive agents, optimizing viscosity for subsequent processing. These mixtures are then precisely coated onto aluminum (cathode) or copper (anode) current collectors using automated slot-die or doctor-blade coating systems. Uniform thickness and strong adhesion are critical quality metrics—any inconsistency can lead to localized hotspots, internal resistance spikes, or capacity imbalances during charge-discharge cycling, ultimately compromising battery performance and lifespan.

After coating, the wet electrodes pass through precisely controlled multi-zone ovens to gradually evaporate residual solvents, leaving behind porous yet mechanically robust composite layers on the current collectors. This drying phase requires meticulous regulation of temperature, airflow, and residence time across each oven zone to prevent the formation of cracks, shrinkage, or delamination of the electrode coating. Rapid, uncontrolled drying can trap solvent vapors inside the layer, creating defects that undermine structural integrity and electrochemical performance. By contrast, a staged drying process ensures uniform solvent removal, preserving the designed porous structure critical for ion transport. Subsequently, the fully dried electrodes undergo calendering—a high-pressure rolling process that compresses the coating to achieve optimal density and porosity tailored to specific battery chemistries. This step uses precision rollers to apply consistent pressure across the electrode surface, enhancing the packing of active material, conductive additives, and binder particles. Proper calendering not only boosts ionic conductivity by shortening ion diffusion pathways but also ensures intimate contact between individual particles and the current collector. These improvements directly translate to enhanced rate capability, higher energy density, and longer cycle life, making calendering a pivotal step in optimizing the overall performance of sodium-ion batteries.

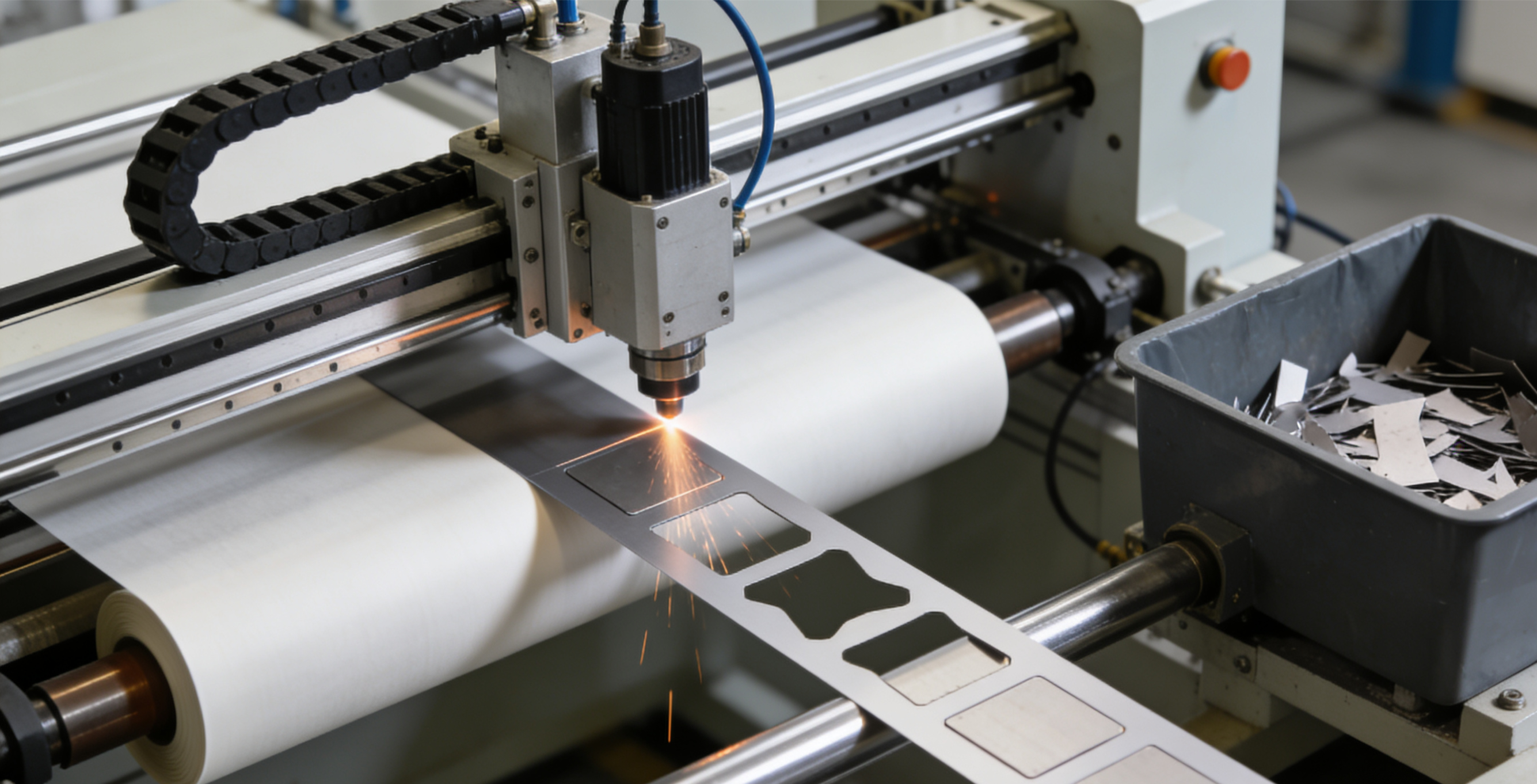

The continuous electrode webs are then slit into narrower strips matching the target cell dimensions. Laser or mechanical cutting tools trim the electrodes into precise shapes (e.g., rectangles for prismatic cells or long strips for cylindrical formats). Edge quality is monitored closely, as burrs or irregularities can cause internal short circuits during cell assembly.

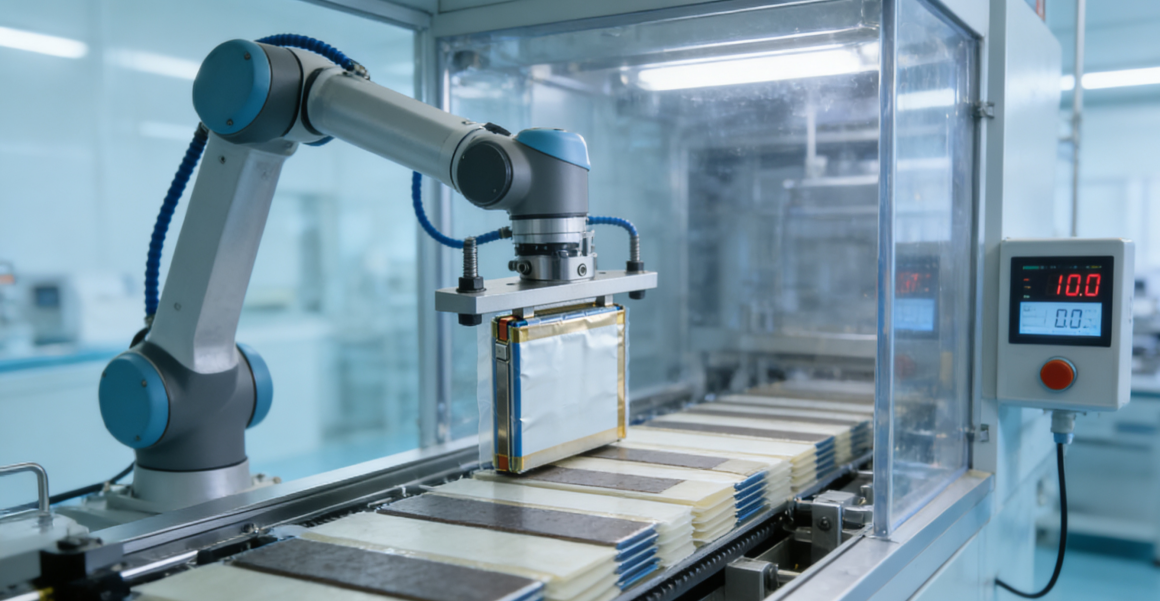

Sodium-ion cells are assembled in low-humidity (<1% RH) dry rooms to prevent moisture-induced side reactions. The process begins with stacking or winding the anode-separator-cathode layers into a “cell stack.” Separators—typically microporous polyolefin films infused with electrolyte-compatible coatings—act as ion-conducting barriers that prevent electrical contact between electrodes. For pouch cells, the stack is inserted into an aluminum-laminated film casing; for cylindrical or prismatic designs, it’s housed in metal cans.

In a controlled environment, the cell is vacuum-filled with sodium-based electrolyte. This step requires precision: insufficient electrolyte leads to poor ion transport, while excess can compromise safety and swelling resistance. Once filled, the cell is hermetically sealed—laser-welded for metal cases or heat-sealed for pouch variants—to maintain integrity throughout its operational life.

Newly assembled cells undergo “formation,” a slow initial charge-discharge cycle that activates the electrochemical interfaces and forms a stable solid-electrolyte interphase (SEI) on the anode. This SEI layer is crucial for long-term cyclability and safety. Following formation, cells enter an aging phase (typically several days at elevated temperatures) to identify early failures and stabilize performance parameters.

Each cell is rigorously tested for capacity, impedance, self-discharge rate, and safety compliance (e.g., nail penetration, overcharge). Based on performance metrics, cells are graded and sorted for specific applications—high-power variants for EVs, high-energy types for stationary storage, etc.

From raw material selection to final validation, the sodium-ion battery manufacturing process merges materials science, precision engineering, and stringent quality control. As production scales globally, ongoing innovations in electrode design, electrolyte formulation, and automation will further enhance efficiency, reduce costs, and solidify Na-ion technology’s role in the clean energy transition.